Automation

RP Template Filler

RP Template Filler

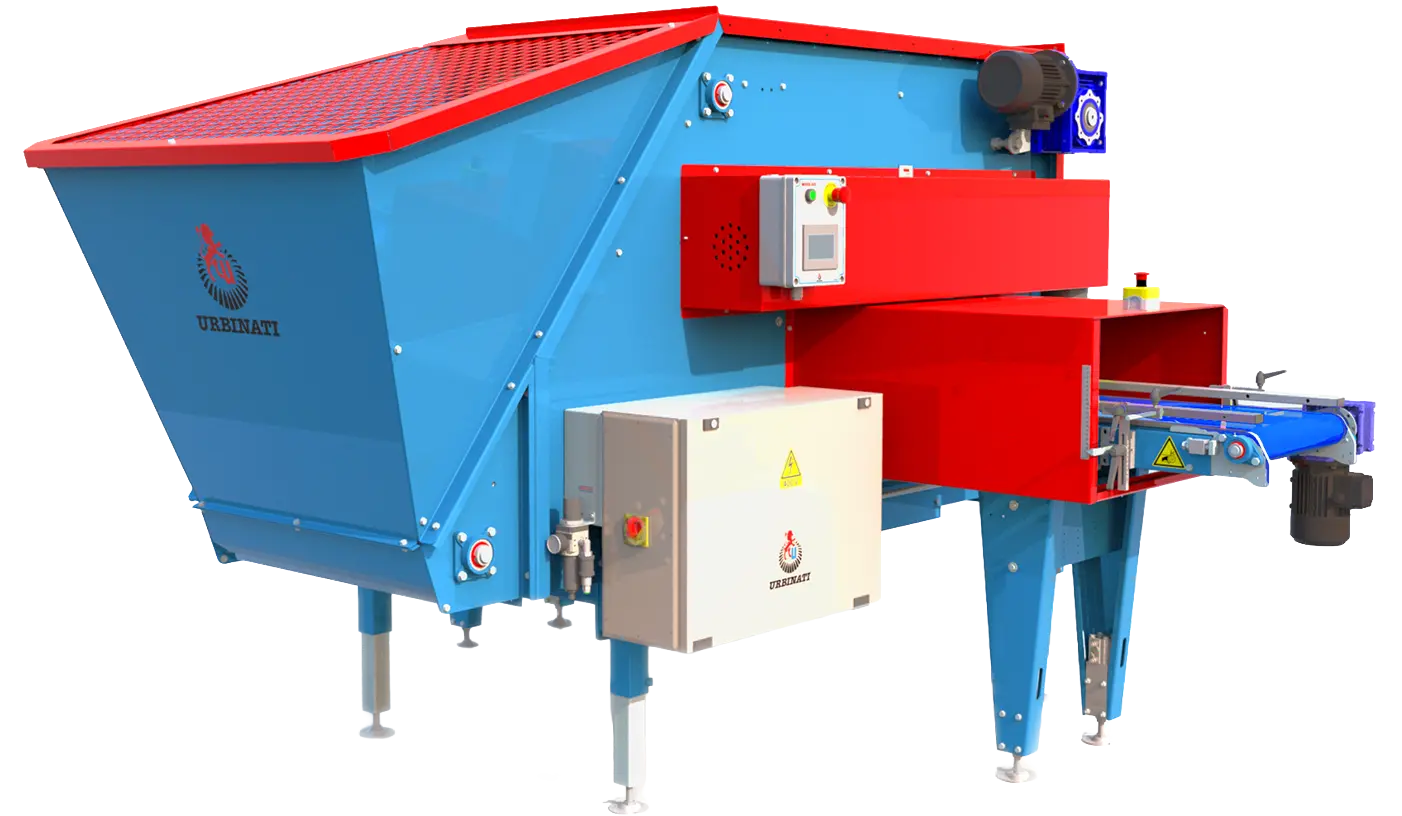

Fill round or square pots in shuttle trays, marketing trays, hydroponic trays, or ornamental containers and baskets. Cross-rotor with steel blades controls adjustable soil density and compaction.

Central unit auto-adjusts filling height via touchscreen while conveyor stays at fixed height—perfect for production line integration. Mechanical components isolated from soil contact for predictable maintenance. Custom masks ensure precise, uniform, waste-free filling at up to 600 containers/hr.

For pricing and additional information, contact the AdeptAg Sales team.

Details

Related Products

Custom Solutions for your Operations

Connect with our experts to explore horticulture solutions that drive efficiency and sustainability.