Automated Shipping System

Automated Shipping System

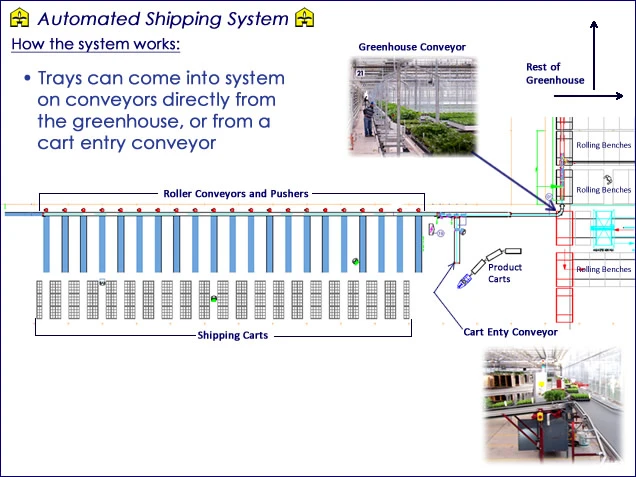

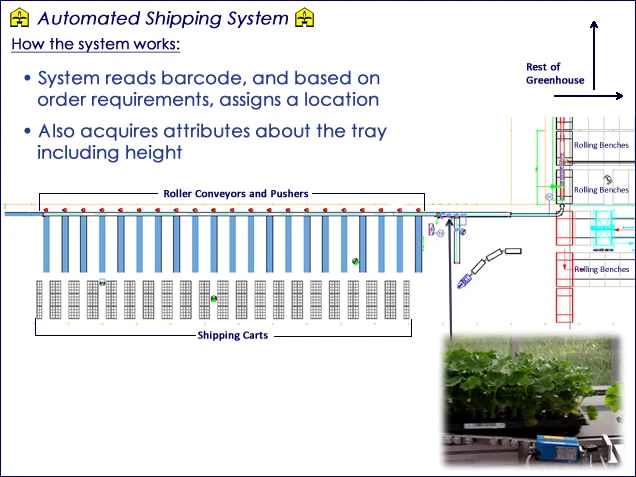

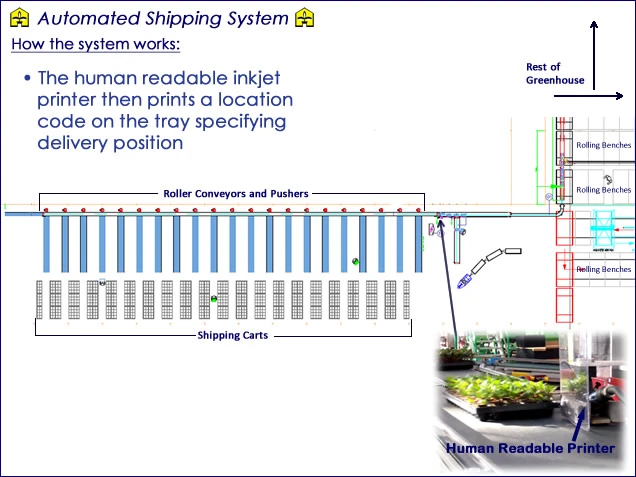

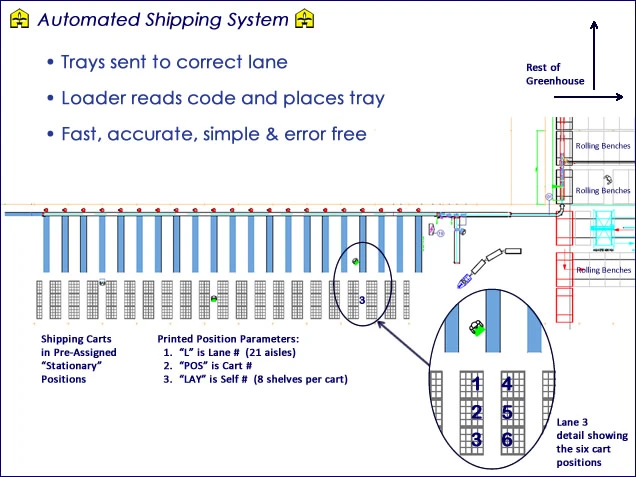

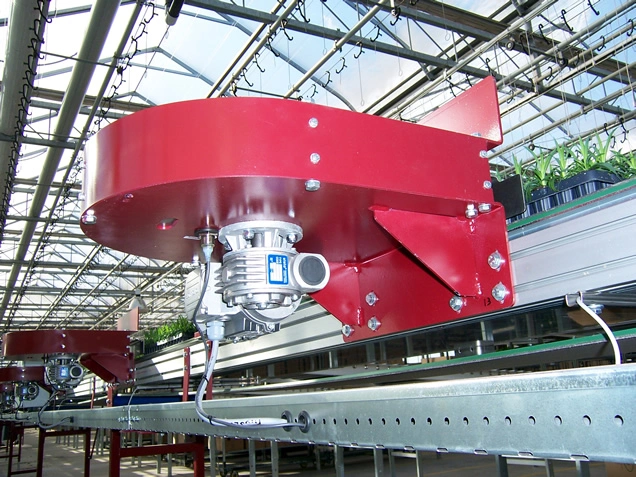

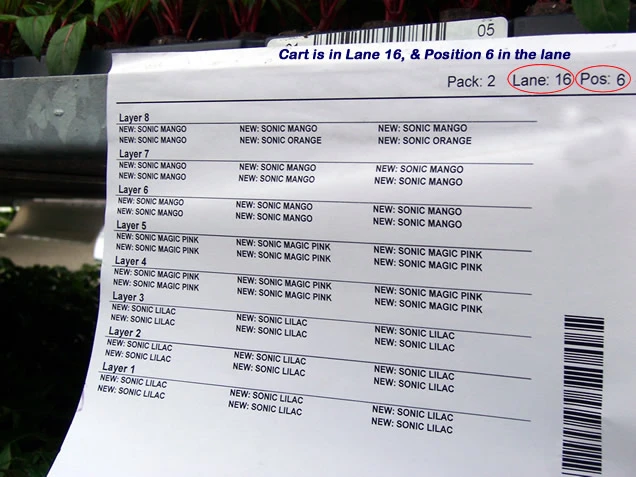

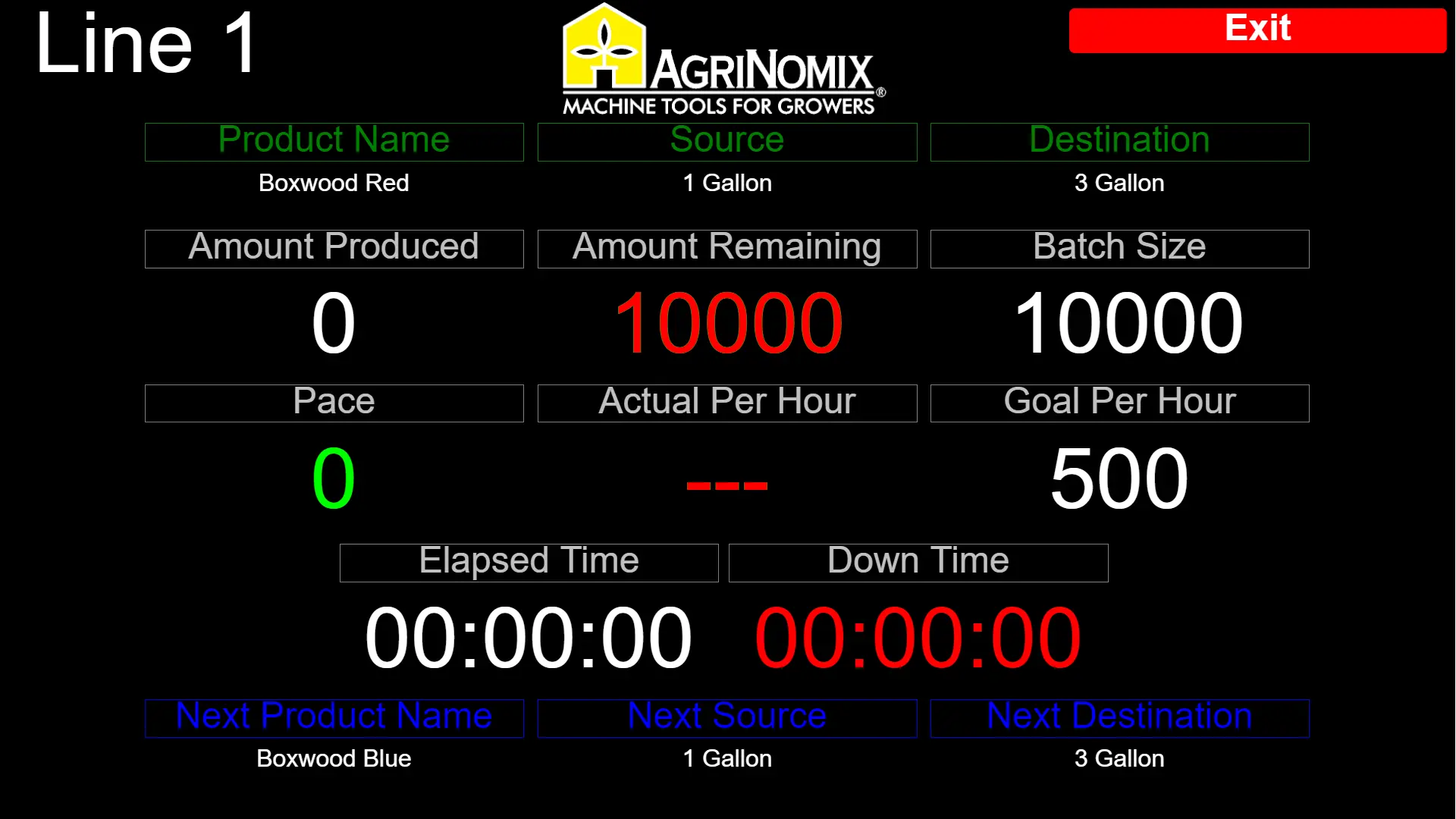

The Automated Shipping System eliminates chaotic "grocery shopping" to fill orders. Product moves directly to stationary shipping carts in a coded grid; workers read simple location codes printed on trays for error-free loading. Integrates with your Master Pick List. Systems handle 1500–2250+ trays per hour. Accepts trays from greenhouse conveyors or cart entry. Bench running capability kicks non-order trays for consolidation. Reduces labor, eliminates shipping errors, gets orders out on time.

For pricing and additional information, contact the AdeptAg Sales team.

Details

Related Products

Custom Solutions for your Operations

Connect with our experts to explore horticulture solutions that drive efficiency and sustainability.