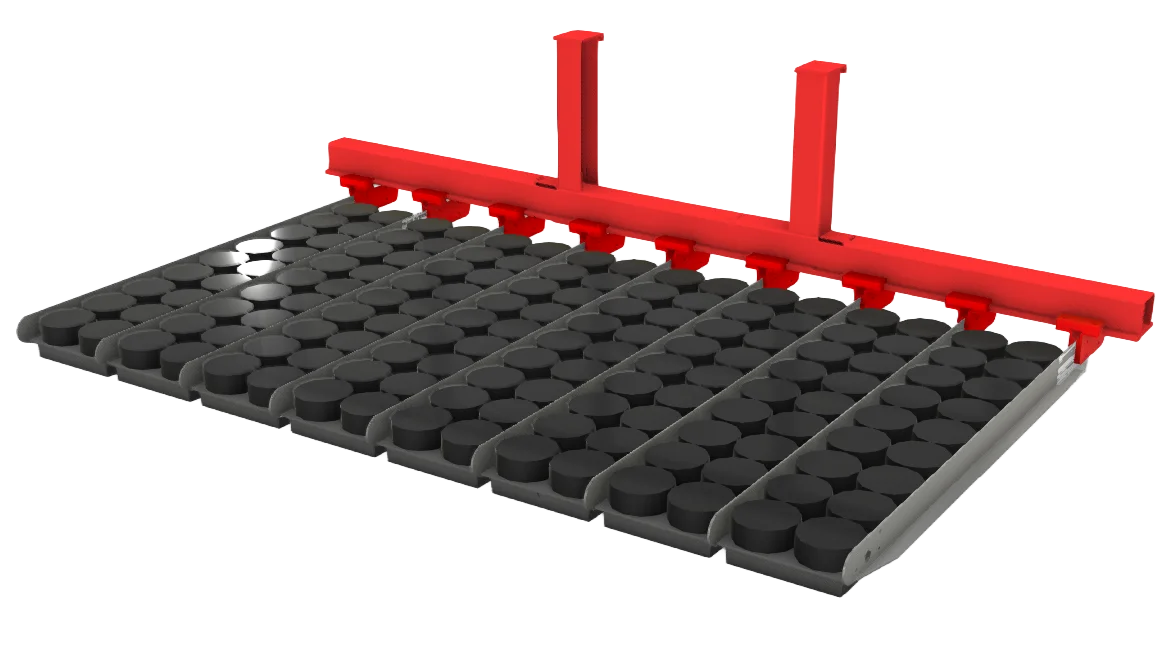

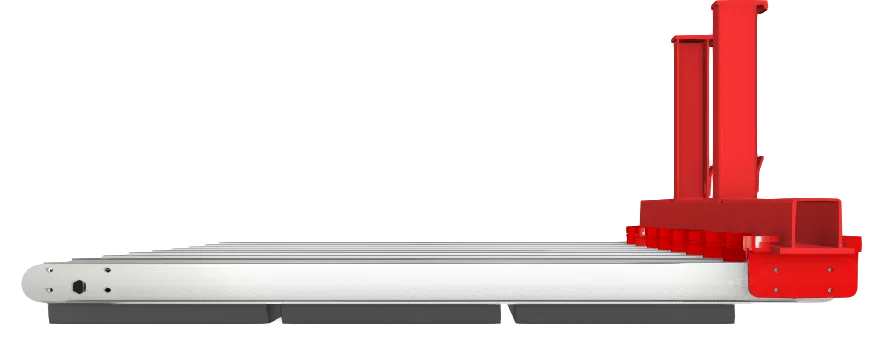

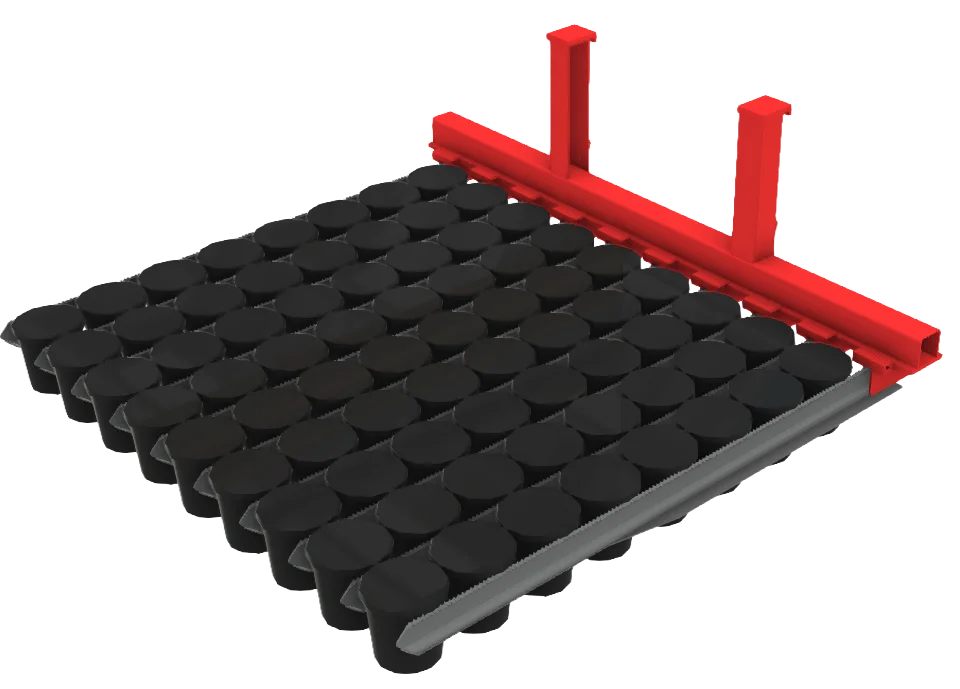

AdeptAg Tray Forks

AdeptAg Tray Forks

Dramatically reduce labor required to move plant trays around a greenhouse or nursery. Move hundreds of plants at once with one person—eliminating double handling onto carts and off again by hand. Pairs with production and shipping buffer belt systems for maximum material handling efficiency. Each fork custom-designed based on your trays, wagon size, and facility layout. Rugged mast handles over 2,000 lbs. Inverted "T" shaped tines pick up low-profile trays. Fits Prins and traditional forklifts.

For pricing and additional information, contact the AdeptAg Sales team.

Details

Related Products

Custom Solutions for your Operations

Connect with our experts to explore horticulture solutions that drive efficiency and sustainability.